Meet the EXP®2 Ti-LOK™ Fitting with Integral Ferrule

Posted by Optimize Technologies on Jul 26th 2018

Oregon City, OR – July 23, 2018 – Optimize Technologies, a leading provider of premium UHPLC, HPLC and LC/MS parts and consumables, is proud to introduce the latest innovation in hand-tight UHPLC technology: the EXP2 Ti-LOK Fitting with Integral Ferrule.

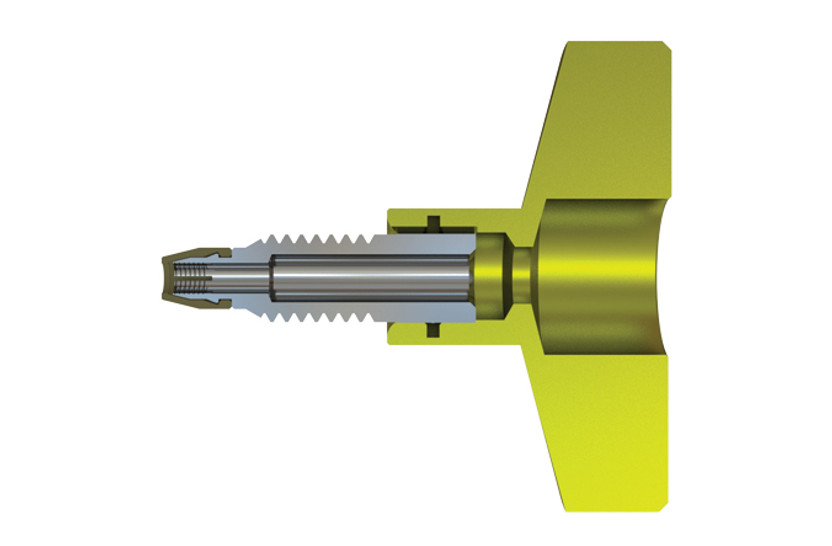

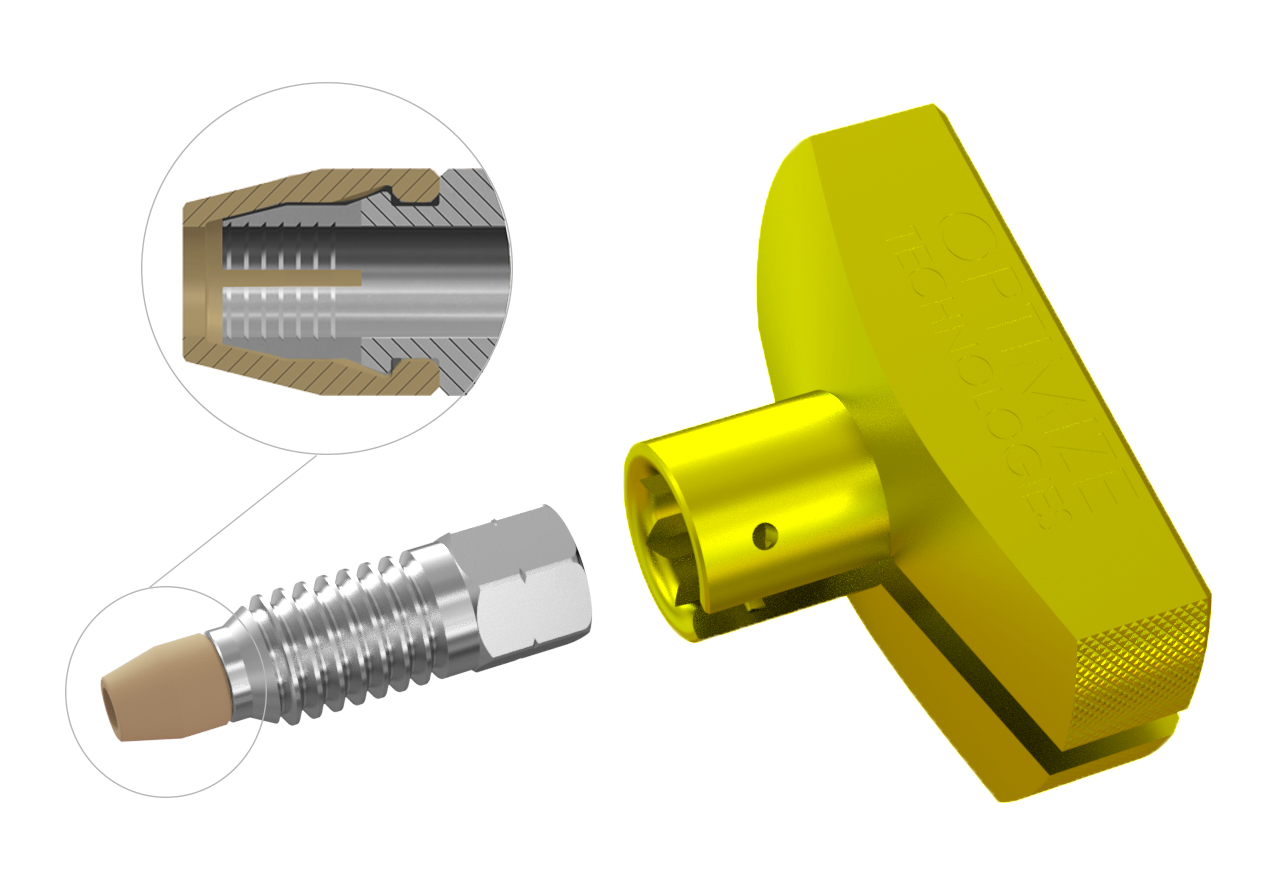

Evolving from Optimize Technologies’ original Titanium Hybrid Ferrule technology, the EXP2 Ti-LOK Fittings feature built-in PEEK ferrules and threaded nuts precision machined from titanium. The new fitting combines the superior corrosion resistance and robustness of titanium with the sealing capability of PEEK. Utilizing a unique geometric design, the fittings firmly press tubing against the tube stop of any instrument port, creating a zero dead volume (ZDV) connection. The ferrule does not permanently swage to the tubing, allowing for many repeat connections and the ability to adjust the tubing to different port depths. Compatible with PEEK, PEEKsil®, Hastelloy C and stainless steel tubing.

Included with the fittings is an EXP2 Driver - a small, easy to use knurled torque driver that snaps onto the nuts for hand-tightening and loosening. The EXP2 Driver is slotted and can be removed from the nut and tubing after use.

KEY FEATURES

- Hand-Tight to 18,000+ psi (1,250+ bar)

- Titanium nut with integral PEEK ferrule

- One-piece fitting (no loose ferrules)

- Robust design offering superior corrosion resistance

- Auto-adjusting zero-dead-volume connection

- Intended for many repeat uses

- Releases tubing for easy repositioning into different ports

- No more cut-off and replacement of swaged ferrules

- Simple and versatile - can be used in all LC applications

- Compatible with PEEK, PEEKsil, Hastelloy C and stainless steel tubing

- Made in the USA

Click to visit the EXP2 Ti-LOK Fitting page for more information...